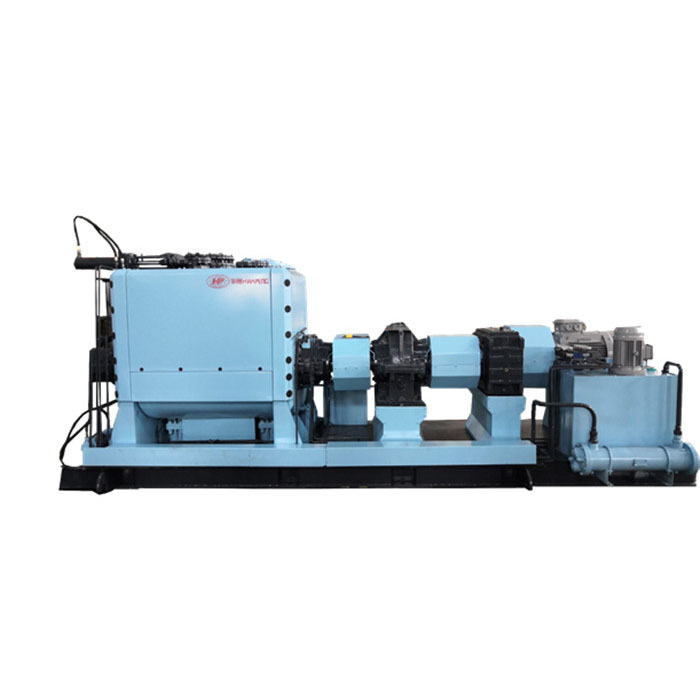

HP-H(H)KC High Efficient Preheating Kneading Cooling System for Special Graphite

HP-H(H)KC Series Phahameng e sebetsang hantle Preheating Kneading Cooling System e sebelisoa haholo-holo ho lokisetsa peista indastering ea carbon, bakeng sa tlhahiso ea anode prebaked, aluminium cathode, graphite electrode, graphite khethehileng le lihlahisoa tse ling.Ka mor'a hore motsoako o futhumale ho mocheso o boletsoeng mochineng oa preheating, o kena ka mochine oa ho luba ho tlatsa ho luba ha thepa e omeletseng le sekontiri se tlamang, ho etsa pente ka polasetiki e ntle, 'me pente e kena mochine o pholileng hore o pholile. mocheso o boletsoeng oa sebopeho.

HP-H(H)KC High Efficient Preheating Kneading Cooling System e na le tanka e ncha e sebetsang hantle ea mocheso o phahameng, lehare la ho kopanya mocheso o phahameng, mokhoa oa ho lekola polokeho ea motsoako oa rotary, sesebelisoa se secha sa ho tiisa sa ho kopanya blade shaft end, ts'ireletso ea polokeho. sesebelisoa sa ho kopanya lehare, mokhoa oa sebele oa ho hlahloba nako ea ho kopanya lehare, sesebelisoa sa ho fepa junifomo, tsamaiso ea phetisetso e nang le bokhoni bo matla ba ho jara le ts'ebetso e ka tšeptjoang, sebaka se loketseng sa poleiti ea lining, sesebelisoa se nepahetseng sa ho lekanya mocheso, joalo-joalo, ho netefatsa hore lisebelisoa li sebetsa hantle. , e tsitsitseng le e ka tšeptjoang.

Ts'ebetso ea tekheniki

Ka mor'a ho phekoloa ka holim'a metsi, bokaholimo ba karolo e kobehileng le holim'a lehare le kopanyang le fihla ho 0.1, lisebelisoa tse kopanyang le tse pholileng li fapane, ha ho bonolo ho khomarela lehare la ho kopanya, 'me bophelo ba tšebeletso ea lehare la ho kopanya ke lilemo tse 20.

E amohela theknoloji e ncha ea tanka e sebetsang hantle haholo, theknoloji e phahameng ea mocheso o phahameng oa mocheso o phahameng oa mocheso, theknoloji e kopanyang ea patent ea ho futhumatsa lehare, theknoloji e ncha ea ho futhumatsa ea patent le theknoloji e nang le tokelo ea ho futhumatsa sebakeng se felletseng.Thepa e omeletseng e na le lebelo la ho futhumatsa ka potlako le bokhoni bo phahameng ba ho futhumatsa.

Karolo e ommeng e kopanyang preheating e nka tangent, lebelo le fapaneng le radius e omeletseng e kopanyang le theknoloji ea ho futhumatsa ho kopanya lisebelisoa ka ho lekana.

Kneading ea peista e sebelisa lehare la ho kopanya la synchronous, e leng theknoloji ea ho kopanya e fetang holimo.Lisebelisoa li kneated ka mokhoa o ts'oanang ntle le ho luba mahlo a mahlo le ho thibela lisebelisoa tse tala.

Ho hlomelloa ka 'mokelli oa lerōle ho bokella lerōle le lokolotsoeng nakong ea ho fepa thepa e omileng ka mokhoa o omileng oa ho kopanya le ho sireletsa tikoloho.Lerōle le bokelitsoeng le tla khutla ka mokhoa o itekanetseng' me le tsoele pele ho kenya letsoho ts'ebetsong e omeletseng ea ho kopanya ho netefatsa ho leka-lekana ha thepa le boleng ba sehlahisoa.

Theknoloji e nang le tokelo ea molao ea kopano e ncha ea ho lekanya mocheso oa thermosensitive e amohetsoe, ka tekanyo e nepahetseng ea mocheso le phoso ea tekanyo ea mocheso ea ± 2 ℃.

Theknoloji ea patent e kopantsoeng ea tšepe ea tšepe ea tšepe e kopantsoeng e amohetsoe ho netefatsa hore ha ho na phofshoana ea carbon e lutlang qetellong ea lehare le kopanyang.

Tanka e entsoe ka poleiti ea tšepe e matla e tlase ea alloy Q460D.Sebaka se ka hare sa tanka se tšoaroa ka sekhahla se holimo sa 0.1.Lisebelisoa ha li bonolo ho khomarela tanka .Bophelo ba tšebeletso ea tanka ke lilemo tse 20.

Welding resistant welding layer e koahetsoe ka holim'a lehare le kopanyang, 'me bophelo ba tšebeletso ea lehare la ho kopanya ke lilemo tse 20.

Sistimi ea ho laolla e amohela phetoho ea haeteroliki ho notlela heke ea ho laolla ho netefatsa hore ha ho na lintho tse lutlang.Tanka le heke ea ho tsoa li ke ke tsa tsoa phofshoana ea khabone.

Lehare le kopanyang le etselitsoe hore le tsamaee ho thibela lehare le tsoakang hore le se ke la futhumatsoa, le atolosoa le ho khomarela; Lehare le kopanyang le na le lisebelisoa tse peli tsa mahlakoreng a mabeli ho thibela lehare le kopanyang ho sila tanka.

Tanka e na le sebopeho se arohaneng, 'me kou ea ho fepa le kou ea pokello ea lerōle li bolokiloe sekoahelong se ka holimo.

E na le tsamaiso ea nako ea sebele ea ho shebella mocheso oa mocheso oa mochine o moholo, alamo hang-hang ha ho e-na le ntho e sa tloaelehang. The shaft e ka sehloohong e nang le pholileng le tsamaiso ea ho shebella e na le lisebelisoa tsa ho pholisa shaft e kholo ka nako ea sebele, ho shebella mocheso oa mocheso o pholileng, ho phalla le likarolo tse ling ka nako ea sebele, 'me u fane ka alamo hang-hang haeba ho e-na le ntho e sa tloaelehang.Ho netefatsa ts'ebetso e sireletsehileng, e ka tšeptjoang le e tsitsitseng ea tsamaiso ea ho beleha ha spindle sebakeng sa mocheso o phahameng.

Ho hlomelloa ka lisebelisoa tsa ts'ireletso ea li-blades tse kopanyang.Khaola matla hang-hang ho sireletsa lehare la ho kopanya ho senya ha ho ka ba le overloading.Ka mor'a hore mojaro o khutlele ho tloaelehileng, ka ho toba qala mochine o moholo, sesebelisoa sa tšireletso ea tšireletso se kopanya le ho tsosolosa matla, 'me tsamaiso e khutlela mosebetsing o tloaelehileng.

Tekheniki Parameters

| Mochini o khethehileng oa graphite o omileng oa preheating | HP-DMH(H)600-SG | HP-DMH(H)2000-SG | HP-DMH(H)3000-SG |

| Bolumo bo lekantsoeng (L) | 600 | 2000 | 3000 |

| Bolulo bo Holimo (L) | 1150 | 3680 | 3900 |

| Phetoho ea ho kopanya Blade (RPM) | 16/13 | 12/15 | 12/15 |

| Mokhoa oa ho futhumatsa | Oli e fetisang mocheso | Oli e fetisang mocheso | Oli e fetisang mocheso |

| Khatello ea Mosebetsi (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |

| Mokhoa oa ho duba | Radius e fapaneng ea lebelo | Radius e fapaneng ea tangent | Radius e fapaneng ea lebelo |

| Kneader e khethehileng ea Graphite | HP-CPK600-SG | HP-CPK2000-SG | HP-CPK3000-SG |

| Bolumo bo lekantsoeng (L) | 600 | 2000 | 3000 |

| Bolulo bo Holimo (L) | 1000 | 3450 | 4800 |

| Mokhoa oa ho duba | mateano a tšoanang velocity superradius | mateano a tšoanang velocity superradius | mateano a tšoanang velocity superradius |

| Phetoho ea ho kopanya Blade (RPM) | 16 ~ 32 (e ka fetoloang) | 16 ~ 32 (e ka fetoloang) | 12 ~ 18 (e ka fetoloang) |

| Mokhoa oa ho futhumatsa | Oli e fetisang mocheso | Oli e fetisang mocheso | Oli e fetisang mocheso |

| Khatello ea Mosebetsi (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |

| Sepholi se khethehileng sa Graphite Paste Kneading Cooler | HP-PKC600-SG | HP-PKC2000-SG | HP-PKC3000-SG |

| Bolumo bo lekantsoeng (L) | 600 | 2000 | 3000 |

| Bolulo bo Holimo (L) | 1000 | 3850 | 5200 |

| Phetoho ea ho kopanya Blade (RPM) | 5 ~ 10 (e ka fetoloang) | 5 ~ 10 (e ka fetoloang) | 5 ~ 10 (e ka fetoloang) |

| Mokhoa oa ho Kopanya | mateano a tšoanang velocity superradius | mateano a tšoanang velocity superradius | mateano a tšoanang velocity superradius |

| Mokhoa oa ho Pholisa | metsi a phodileng | metsi a phodileng | metsi a phodileng |

| Khatello ea Mosebetsi (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |