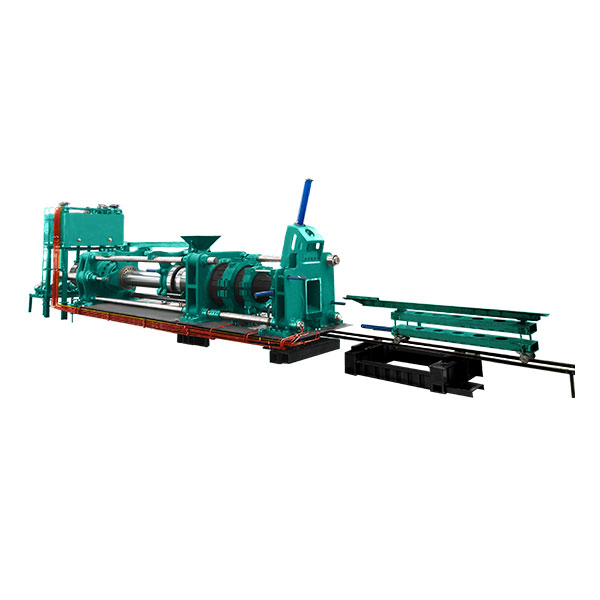

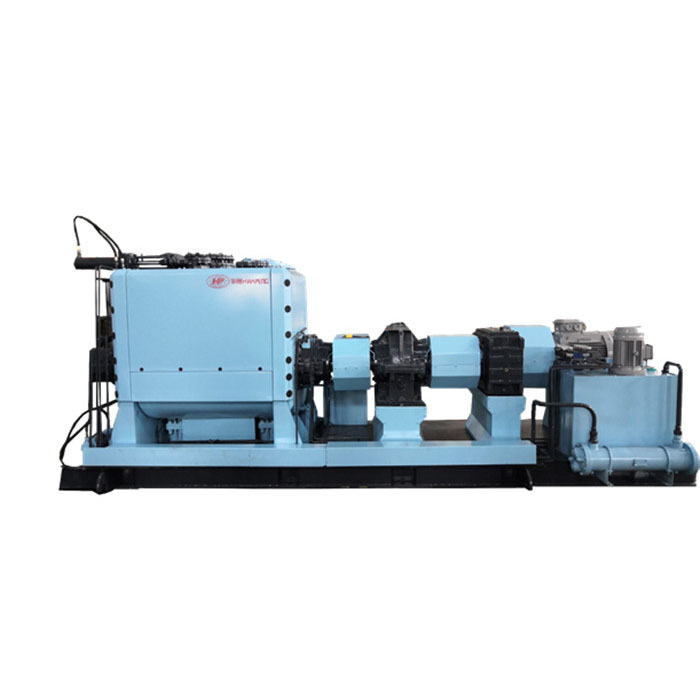

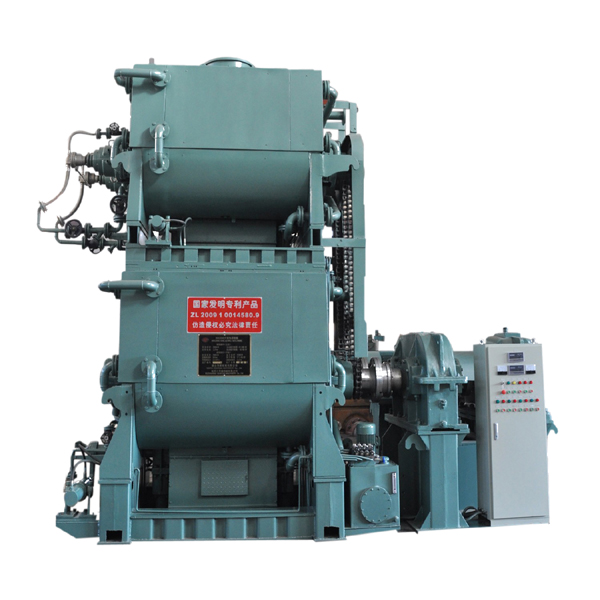

Hp-Cep Series Carbon Extrusion Press

HP-CEP Series Carbon Extrusion Press e sebelisa theknoloji ea hydraulic extrusion le taolo ea premium, theknoloji ea vacuum, theknoloji ea ho futhumatsa ka likaroloana, theknoloji ea ho kuta ka mokhoa o lumellanang, le theknoloji ea PC joalo-joalo ho fana ka tharollo e molemo ka ho fetisisa ea carbon extrusion.

Ts'ebetso ea Setsebi

1. Taolo e nepahetseng ea lebelo la extrusion

Sisteme ea hydraulic e khanna cylinder e kholo ea plunger ho laola ka nepo lebelo la extrusion ea li-electrode tsa graphite le ho netefatsa boleng ba li-electrode tsa graphite.

2. Moqapi o mocha oa die

Moralo oa karolo ea ho fokotsa li-curve tse ngata e kopantsoeng le karolo e khuts'oane ea phetoho e ka ntlafatsa haholo ho theha sekhahla le boleng ba holim'a elektrode ea graphite.

3. Vacuum system

Sistimi ea vacuum e ntša pente nakong ea ts'ebetso ea pele ho trusion le extrusion ho ntša mosi oa molumo ka botlalo le ho ntlafatsa ho etsa le ho qeta boleng ba sehlahisoa, ho fumana nako e khuts'oane ea pele ho extrusion le tlhahiso e sebetsang.

4.Automatic synchronous ho kuta sesebelisoa

E qoba ho arola ka hare, ho atolosoa, ho phunyeha le liphoso tse ling tsa li-electrode tsa graphite tse bakoang ke mochine o tsitsitseng oa ho kuta le ho tiisa boleng ba li-electrode tsa graphite le ho ntlafatsa katleho ea tlhahiso.

5. Mofuta o tsitsitseng kamoreng e le 'ngoe ea thepa

Sebopeho se bonolo se tiisa ho boloka litšenyehelo tsa thepa, sebopeho sa infra le lisebelisoa tse tšehetsang, le ts'ebetso e tšepahalang le tlhokomelo e bonolo.

6. Taolo e nepahetseng ea mocheso oa kamore ea thepa le ho shoa ka mekhahlelo

Likamore tsa thepa le li-dies li futhumatsoa ka taolo e nepahetseng ea mocheso ka mekhahlelo ho netefatsa boleng bo tsitsitseng ba electrode ea graphite.

7.Ho khutla ka potlako ho thusoa ke cylinder e thusang

Li-cylinders tse thusang li na le boikarabello ba ho khutla ka potlako ha molamu oa extrusion ho ntlafatsa katleho ea mosebetsi.

8. Sistimi ea taolo ea Hydraulic

Sistimi e tsebahalang ea malapeng le mose ho maoatle, li-valve le li-filtering le seteishene sa pompo se amohelang sistimi e ikemetseng ea potoloho li sebelisoa ho netefatsa ts'ebetso e tsitsitseng le e ts'epahalang ea hydraulic system.Khokahano ea lipeipi tse nang le flanged e tiisa ho tiisoa ho ka tšeptjoang le ho lutla ha zero ha liphaephe tsa hydraulic system tlas'a maqhubu a mangata a khatello e phahameng.

9. PLC taolo e iketsang

Taolo ea othomathike ea PLC e sebelisoa ho beha likarolo tsa bohlokoa tsa ts'ebetso le ho laola ts'ebetso ka bo eona, sistimi e sebetsa ka bo eona e netefatsang litekanyetso tsa ts'ebetso ea tlhahiso le botsitso ba boleng, tlhahiso e ntlafatsoa mme litšenyehelo tsa tlhahiso li fokotsehile.