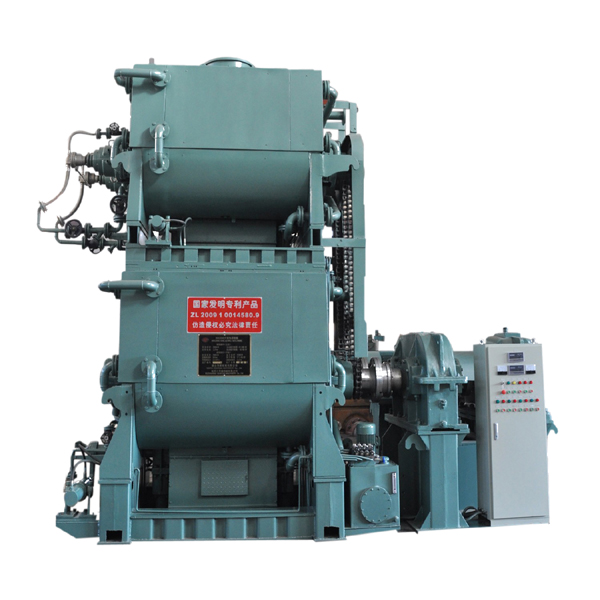

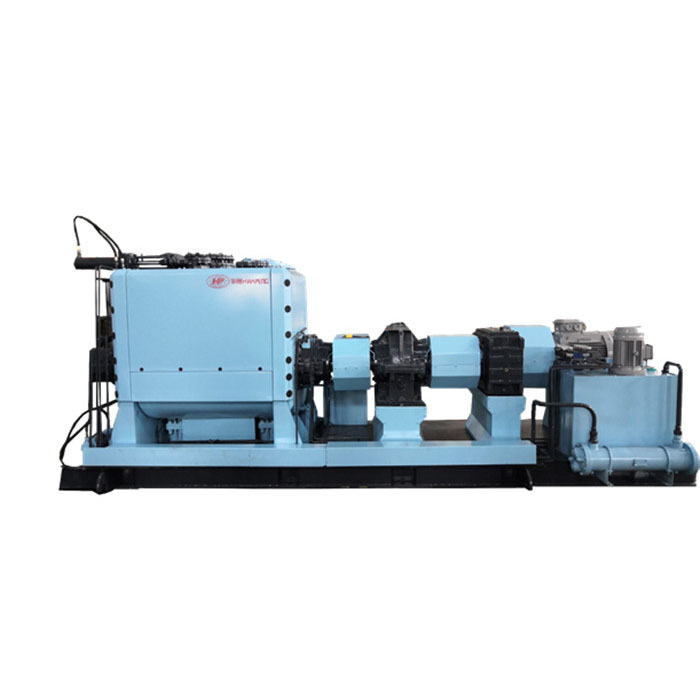

Hp-Evc Series Extrusion Vibrocompactor

Ts'ebetso e hlahelletseng ea boleng bo phahameng ba anode mme ha ho na lekhalo le kahare <ka lebaka la sistimi e ntle ea hydraulic le vacuum system, e etsang anode e tšepahalang ka ho fetisisa e nang le ts'ebetso e ntle ea mokelikeli.

Ts'ebetso ea Setsebi

1.Four-column-four foreime load guiding guide

Mokhoa oa tataiso oa mochini oa khatiso oa extrusion o sebelisoa ho HP-EVC letoto la anode vibrocompactor ka sebopeho se bonolo le tlhokomelo e bonolo.Boima ba ho leka-lekana le hlobo e holimo li na le boemo bo nepahetseng ho fokotsa phapang ea bolelele likhutlong tse 'ne tsa anode.

2. Theknoloji ea vacuum

Theknoloji ea vacuum e hōlile 'me tekanyo e hlokahalang ea vacuum e ka finyelloa nakong ea 2s;Pokello ea mosi e loketse ts'ireletso ea tikoloho;Mapetso a ka hare le a ka ntle a li-block tsa carbon a fokotsehile;Boima ba anode bo eketseha.

3. Theknoloji ea ho fafatsa mokelikeli oa Spacer e tlotsa hantle ebile e boloka litšenyehelo

Mokelikeli oa Spacer ho fapana le oli ea litšila e fafatsoa ka hlobo, litšenyehelo tsa 70% lia bolokoa, tekanyo ea atomization e phahame, mokelikeli oa spacer o fafatsoa ka ho lekana le ka ho lekaneng ntle le thupa ea lintho tse bonahalang.

4. Theknoloji ea khatello e sa khaotseng ea khatello ea makhetlo a mabeli

Theknoloji ea khatello e sa khaotseng ea khatello e habeli e sebelisoa;Tobetsa hlooho e phahamisoa ho tloha ho li-blocks tsa carbon butle, e le hore li-blocks tsa carbon li khutlela morao butle ho qoba mapetsong a ka hare.Li-anode blocks li na le ts'enyo e nyane le ho phatloha ho fokolang ka hare.

5. Mofuta oa naha o nang le tokelo ea molao

Hlobo e lumellana hantle le anode block ka matla a phahameng le mocheso o nyolohang ka potlako, ho bula le ho koala ha chamfer ka boiketsetso, 'me anode block ha e na lebone pheletsong.

6.Moderate block pushing thekenoloji

E le ho qoba ho senyeha kapa ho senyeha ha li-block tsa carbon tse chesang tse bakoang ke tšusumetso e matla, hydraulic cylinder ea block pushing mechanism e nka mokhoa oa ho sututsa ka potlako, o fokotsang deformation ea li-block tsa carbon tse chesang.

7.Theknoloji e nepahetseng ea ho lekanya bophahamo

Bophahamo bo nepahetseng ba carbon block bo bolelele ba ho lekanya theknoloji e tataisang ho lokisoa ha mekhahlelo ea tlhahiso, encoder e romelloang kantle ho naha e sebelisetsoa ho bona bophahamo ba carbon block ea inthaneteng, data e nepahetseng e ka bolokoa le ho hatisoa.

8. Sistimi e tsoetseng pele ea hydraulic e nang le ho nepahala ho phahameng

Sistimi e ntlafalitsoeng ea phetiso le taolo ea haeteroliki e hlophisitsoeng ke sehlopha sa litsebi se entsoeng ka litsebi tsa tekheniki tsa taolo ea haeteroliki, taolo ea motlakase le sebopeho sa mochini.

9. Motlakase o ikemetseng le boitsebiso ba fektheri

Litharollo tsa boiketsetso le tsa tlhaiso-leseling tse ipapisitseng le boiphihlelo ba lilemo tse ngata lia phethahala.Ho sebelisoa ntlo ea taolo ea tšepe e se nang mochini oa Rittal.Sistimi ea taolo e tsoa ho ABB kapa SIEMENS, lisebelisoa tse tlase tsa voltage tse tsoang Schneider, 'me li-converter tsa frequency li amohela ABB kapa mefuta e meng e tsebahalang lefatšeng ka bophara.

Mekhoa e mene ea taolo ka ho latellana e loketse tlhahiso kapa tlhokomelo.Taolo ea matsoho le taolo ea othomathike li hlokomela ho fana ka letsoho ntle le moroallo.

Taolo e hole ea komporo ea Host e sebelisoa ho lemoha liphoso, ho rekota data le ho hatisa tlaleho.